Cleaning of Tanks

We carry out the most effective form of petrol tank cleaning once the tank has been degassed and the atmospheric gasses inside it have been controlled and are below 1% of the LFL (lower flammable limit) at all times.

Over time, water and sludge gets deposited in the base of the tanks. These impurities may come from the actual fuel or may be caused by the entry of water or impurities due to a leaky tank or pipework.

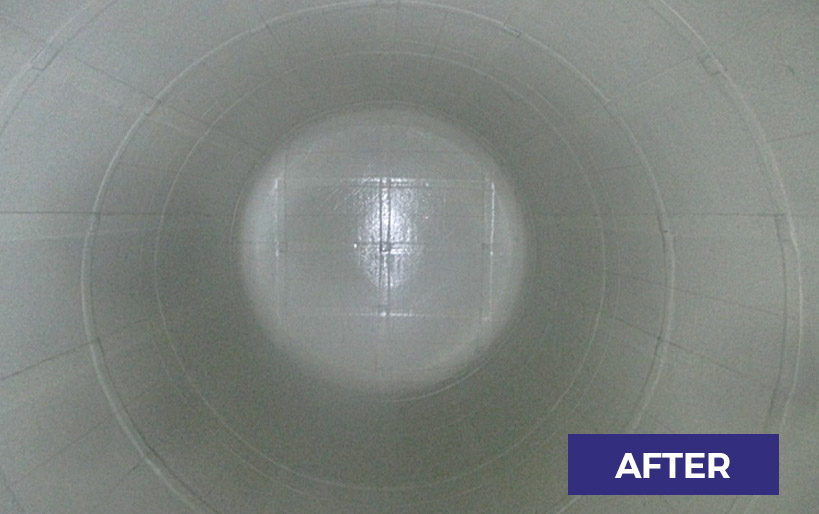

Our waste tank cleaning services begin by removing the sludge from the whole base of the tank, clean the walls with water at high pressure and with disinfectants designed and created by our chemists, and thoroughly brush and dry the tank.

The liquids resulting from the tank cleaning will be packed in appropriate containers for their subsequent transfer to the plant for managing toxic and hazardous wastes.

In this aspect, Rafibra acts as manager-transporter of the sludge sediments and hydrocarbons and other hydrocarbon waste.

The reduction in the explosive index will be verified during this operation and after vacuuming the combustible waste remaining inside the tank.

All ventilation equipment and the tank structure will be connected to an earth.

Oxygen will not be used for ventilation under any circumstances.